Brick and Clay Pavers

Discover what makes clay bricks a superior paving product

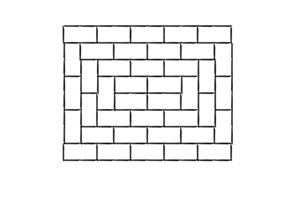

When the client sought a more elegant design by using clay brick pavers, this color choice proved ideal to lighten up this small space. The deeper reds and browns were designed to work with the house materials palette, but it is the golden bricks in the center with their specially smoothed surface that brings light into the composition without changing materials. "While the material cost was higher," says designer Devin Brunke, the installation was identical to that of ordinary concrete unit pavers." Arcadia Design Group in Centennial,CO

The first mass produced pavers were brick, which presented a more cost effective alternative to rounded cobble stone or hand hewn paving stones. This lends a special value to bricks for their suitability in traditional and historic homesites. Brick is the one masonry unit that has never gone out of style, nor will it ever date a project to a particular period.

Devin Brunke of Arcadia Design Group in Centennial, Colorado believes there is a special look to clay pavers. "We feel they're simply more elegant than concrete pavers, the units are more precise, colors are richer and clay is more durable overall. While the installation costs of concrete units is equal to that of clay, the clay paver cost is what drives the price up. Most of our customers don't want the added expense, but for others who are trying to achieve a special appearance, nothing else is acceptable."

Unlike concrete unit pavers, brick is made of clay, which occurs naturally in most states. It is shaped and then fired in ovens to provide the very hard and durable unit that stands the test of time. The origin of the clay itself determines color, which ranges from cream to very dark brown. The majority of bricks are a reddish color. Firing temperatures can also influence brick color. Unlike concrete pavers that are composed of grey concrete stained on the outside, brick color is uniform throughout. If a clay paver is chipped or deeply scratched, there is no change in color.

Brick is a Green Product

Brick is the first unit paver to be recycled. Those harvested from building demolition are known as "used brick," which is highly valued for certain project styles. The labor to clean mortar from used brick can drive its cost well above that of new brick. It may also prove slightly more expensive to lay used brick due to slight variability in size. This is because the bricks originated in different factories, particularly those made long ago when standardization was not as critical. But for those seeking the beautiful blend of subtle color variations unique to used brick, there is no equal.

Surface treatments have been applied to brick to lend the look of used brick without the added expense. These can be difficult to tell from used brick when well done, but often the uniformity of this treatment may not fool the eye at all. In fact, homes where uniform faux used bricks were used in the 1970s are dating these landscapes today.

Iron is also used to darken brick or to create darker textured surfaces for a more sedate appearance.

Brick is the first paver to be laid without mortar, so these patios and walkways were porous before the EPA established guidelines for permeable paving.

Why Choose Brick?

- Colorfast

- Resistance to de-icing damage

- Traditional colors

- Recognized patterns

- Adaptability: on concrete, on sand

Traditional brick pavers are augmented by a curb of natural stone units known as Belgian Blocks. These heavy, hand hewn blocks of granite resemble those old cobblestone pavers of early American cities and are still made today in a variety of stone color. This red cast Belgian Block provides a perfect solution for the slight change of grade from the planter to driveway without changing the visual palette. This driveway can be easily constructed to function as solid or porous paving using the high compressive strength of concrete or clay brick. Stone Scapes Design in Hanover, MD

Variation in Brick Size

- The average brick is 8 1/8" long; 3 7/8" wide; 2 7/16" thick.

- A larger brick is made for specific uses including wall caps (11 1/2" by 3 7/8" by 2 1/4").

- Brick can also be formed into any shape for specialty projects.

- Some companies are creating sets of brick in varied sizes to offer a clay product with the variable patterns made popular by concrete pavers and interlocking pavers.

Brick Paver Glossary

Bull Nose:

One end of the brick is rounded for use in step treads, swimming pool coping and wall caps.Beveled Edge:

For a more cobbled appearance, a beveled edge brick provides more visual texture and patterns tend to stand out more when used without mortar.Scalloped Edge:

An undulating or zig-zag edge is not widely used but is available for specialty brick paving.Tumbled Edge:

This technique makes a new brick look much older to better adapt to historic projects or homes where an age old look is desired.Weathering

Brick is made by two processes. Molded brick will be equally smooth on all sides. Extruded brick features a wire cut edge that provides the most non-slip textured surface for difficult climates. Brick quality is based on three grades of weathering:- Negligible weathering - California, Gulf Coast, Florida

- Moderate weathering - Midwest

- Severe weathering - New England, North and Northeastern states

Brick VS Concrete Pavers:

| Characteristic | Clay Brick | "Concrete Unit Paver |

|---|---|---|

|

Size range |

Square/rectangle |

Variable |

|

Pattern options |

Limited |

Unlimited |

|

Origin |

USA |

USA and imported |

|

Color range |

Limited |

Wide variation |

|

Colorfastness |

High |

Moderate |

|

Styles |

Traditional |

No limit |

|

Wear |

Chips and cracks |

Surface erosion |

|

Lifespan |

Generations |

Decades |

|

Sealing |

yes |

optional |

Backyards

Backyards

Front Yards

Front Yards